ท่อ ASTM A333

ท่อเหล็ก ASTM A333 คืออะไร?

ท่อเหล็ก ASTM A333 เป็นข้อกำหนดมาตรฐานสำหรับท่อเหล็กคาร์บอนและเหล็กอัลลอยด์แบบไร้รอยต่อและแบบเชื่อม สำหรับการใช้งานที่อุณหภูมิต่ำหรือการใช้งานอื่นๆ ที่ต้องการความเหนียวในการรับแรงเฉือน มาตรฐานนี้ครอบคลุมเหล็กเฟอร์ริติกหลายเกรด ได้แก่ เกรด 1, เกรด 3, เกรด 4, เกรด 6, เกรด 7, เกรด 8, เกรด 9, เกรด 10 และเกรด 11 Metals-Piping จัดจำหน่ายท่อเหล็ก ASTM A333 ที่ผลิตโดยกระบวนการไร้รอยต่อหรือแบบเชื่อม โดยไม่มีการเติมโลหะตัวเติมในขั้นตอนการเชื่อม ยกเว้นเกรด 4 ที่จะผลิตโดยกระบวนการไร้รอยต่อเท่านั้น ท่อที่จัดส่งจะต้องปราศจากการซ่อมแซมด้วยการเชื่อม โดยผ่านการทดสอบด้วยรังสีเอกซ์หรือการตรวจสอบด้วยคลื่นเสียงอัลตราโซนิค

ดาวน์โหลด

ข้อกำหนดองค์ประกอบทางเคมีของท่อเหล็ก ASTM A333

| องค์ประกอบทางเคมีของ ASTM A333 | |||||||||

| องค์ประกอบ | เกรด 1, % | ชั้นประถมศึกษาปีที่ 3, % | ชั้นประถมศึกษาปีที่ 4, % | ชั้นประถมศึกษาปีที่ 6, % | ชั้นปีที่ 7, % | ชั้นมัธยมศึกษาปีที่ 8, % | ชั้นมัธยมศึกษาปีที่ 3, % | เกรด 10, % | ชั้นมัธยมศึกษาปีที่ 4, % |

| C | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Mn | 0.40–1.06 | 0.31–0.64 | 0.50–1.05 | 0.29–1.06 | 0.90 | 0.90 | 0.40–1.06 | 1.15–1.50 | 0.60 |

| P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| S | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Si | - | 0.18–0.37 | 0.08–0.37 | 0.10 นาที | 0.13–0.32 | 0.13–0.32 | - | 0.10–0.35 | 0.35 |

| Ni | - | 3.18–3.82 | 0.47–0.98 | 0.40 | 2.03–2.57 | 8.40–9.60 | 1.60–2.24 | 0.25 | 35.0–37.0 |

| Cr | - | - | 0.44–1.01 | 0.30 | - | - | - | 0.15 | 0.50 |

| Cu | - | - | 0.40–0.75 | 0.40 | - | - | 0.75–1.25 | 0.15 | - |

| Al | - | - | 0.04–0.30 | - | - | - | - | 0.06 | - |

| V | - | - | - | 0.08 | - | - | - | 0.12 | - |

| Cb | - | - | - | 0.02 | - | - | - | 0.05 | - |

| Mo | - | - | - | 0.12 | - | - | - | 0.05 | 0.50 |

| Co | - | - | - | - | - | - | - | - | 0.50 |

*สำหรับเกรด 1 และ 6 การลด C ลง 0.01% ต่ำกว่า 0.30% จะอนุญาตให้เพิ่ม Mn ขึ้น 0.05% สูงกว่า 1.06% ได้ โดยมีค่าสูงสุดไม่เกิน 1.35%

*สำหรับเกรด 6 ขีดจำกัดของโคลัมเบียมอาจเพิ่มขึ้นได้ถึง 0.05% ในการวิเคราะห์ความร้อน และ 0.06% ในการวิเคราะห์ผลิตภัณฑ์

*โดยทั่วไป ค่าเทียบเท่าคาร์บอน CE = [C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15] จะต้องไม่เกิน 0.43% จากการวิเคราะห์ด้วยความร้อน

คุณสมบัติเชิงกลของท่อเหล็ก ASTM A333

| เอสเอเอสทีเอ333 | ความแข็งแรงดึงขั้นต่ำ | ความแข็งแรงครากขั้นต่ำ | เปอร์เซ็นต์การยืดตัวขั้นต่ำ | |||

| ระดับ | psi | เมกะปาสคาล | psi | เมกะปาสคาล | ตามยาว | แนวขวาง |

| ชั้นประถมศึกษาปีที่ 1 | 55,000 บาท | 380 | 30,000 | 205 | 35 | 25 |

| ชั้นประถมศึกษาปีที่ 3 | 65,000 บาท | 450 | 35,000 | 240 | 30 | 20 |

| ชั้นประถมศึกษาปีที่ 4 | 60,000 | 415 | 35,000 | 240 | 30 | 16.5 |

| ชั้นประถมศึกษาปีที่ 6 | 60,000 | 415 | 35,000 | 240 | 30 | 16.5 |

| ชั้นประถมศึกษาปีที่ 7 | 65,000 บาท | 450 | 35,000 | 240 | 30 | 22 |

| เกรด 8 | 100,000 | 690 | 75,000 | 515 | 22 | - |

| เกรด 9 | 63,000 บาท | 435 | 46,000 | 315 | 28 | - |

| ชั้นมัธยมศึกษาปีที่ 4 | 80,000 | 550 | 65,000 บาท | 450 | 22 | - |

| ชั้นมัธยมศึกษาปีที่ 11 | 65,000 บาท | 450 | 35,000 | 240 | 18 | - |

*ค่าการยืดตัวที่ระบุไว้เป็นค่าที่ได้จากการทดสอบกับชิ้นงานทรงกลมมาตรฐานขนาด 2 นิ้ว หรือ 50 มม. (หรือ 4D)

*ค่าการยืดตัวของเกรด 11 ใช้สำหรับผนังทุกขนาดและขนาดเล็กที่ทดสอบในส่วนตัดขวางทั้งหมด

การทดสอบแรงกระแทกแบบ Charpy V-notch ของท่อเหล็ก ASTM A333

| ข้อกำหนดด้านผลกระทบสำหรับระดับชั้นประถมศึกษาปีที่ 1, 3, 4, 6, 7, 9, 10 และ 11 | ||||

| ขนาดของตัวอย่าง | *A | *B | ||

| mm | ฟุต·ปอนด์ | J | ฟุต·ปอนด์ | J |

| 10 x 10 | 13 | 18 | 10 | 14 |

| 10 x 7.5 | 10 | 14 | 8 | 11 |

| 10 x 6.67 | 9 | 12 | 7 | 9 |

| 10 x 5 | 7 | 9 | 5 | 7 |

| 10 x 3.33 | 5 | 7 | 3 | 4 |

| 10 x 2.5 | 4 | 5 | 3 | 4 |

*A หมายถึงค่าเฉลี่ยต่ำสุดของแรงกระแทกจากแท่งบากในแต่ละชุดตัวอย่างสามชิ้น

*B หมายถึงค่าแรงกระแทกต่ำสุดของแท่งบากของชิ้นงานทดสอบเพียงชิ้นเดียวจากชุดชิ้นงาน

| อุณหภูมิการทดสอบแรงกระแทกขั้นต่ำของ ASTM A333 | ||

| ระดับ | °F | °C |

| 1 | -50 | -45 |

| 3 | -150 | -100 |

| 4 | -150 | -100 |

| 6 | -50 | -45 |

| 7 | -100 | -75 |

| 8 | -320 | -195 |

| 9 | -100 | -75 |

| 10 | -75 | -60 |

| 11 | -320 | -195 |

* การทดสอบแรงกระแทกที่ระบุไว้สำหรับอุณหภูมิต่ำกว่า 70 °F [20 °C] ควรดำเนินการด้วยความระมัดระวัง

ท่อไร้รอยต่อและท่อเชื่อมทั้งหมดที่ผลิตตามมาตรฐาน ASTM A333 ยกเว้นเกรด 8 และ 11 จะต้องผ่านการอบชุบความร้อนเพื่อควบคุมโครงสร้างจุลภาคตามวิธีการใดวิธีการหนึ่งต่อไปนี้:

ทำให้เป็นปกติโดยการให้ความร้อนจนถึงอุณหภูมิสม่ำเสมอไม่น้อยกว่า 1500 °F [815 °C] แล้วทำให้เย็นลงในอากาศหรือในห้องเย็นของเตาอบที่ควบคุมบรรยากาศ หรือทำให้เป็นปกติอย่างที่กล่าวไว้ข้างต้น และตามดุลยพินิจของผู้ผลิต อาจให้ความร้อนซ้ำอีกครั้งจนถึงอุณหภูมิการอบชุบที่เหมาะสม

สำหรับกระบวนการไร้รอยต่อเท่านั้น ให้ทำการอุ่นซ้ำและควบคุมอุณหภูมิการทำงานร้อนและอุณหภูมิของการตกแต่งผิวร้อนให้อยู่ในช่วงอุณหภูมิการตกแต่งผิวตั้งแต่ 1550 ถึง 1750 °F [845 ถึง 945 °C] แล้วทำให้เย็นลงในอากาศหรือในเตาอบที่มีบรรยากาศควบคุมจากอุณหภูมิเริ่มต้นไม่น้อยกว่า 1550 °F [845 °C] หรือดำเนินการตามที่กล่าวมาข้างต้น และตามดุลยพินิจของผู้ผลิต อาจทำการอุ่นซ้ำจนถึงอุณหภูมิการอบชุบที่เหมาะสม

ท่อไร้รอยต่อเกรด 1, 6 และ 10 อาจผ่านกระบวนการอบชุบความร้อนโดยการให้ความร้อนจนถึงอุณหภูมิสม่ำเสมอไม่น้อยกว่า 1500 °F [815 °C] จากนั้นจึงจุ่มลงในของเหลวเพื่อทำให้เย็นลงอย่างรวดเร็ว และให้ความร้อนอีกครั้งจนถึงอุณหภูมิการอบคืนตัวที่เหมาะสม

ท่อเหล็ก ASTM A333 เกรด 8 จะต้องผ่านการอบชุบความร้อนโดยผู้ผลิตด้วยวิธีใดวิธีหนึ่งต่อไปนี้: ชุบแข็งแล้วอบคืนตัว หรือ การอบคืนตัวสองครั้งแล้วอบคืนตัว ในกรณีที่จำเป็น ท่อเหล็กเกรด 11 จะต้องผ่านการอบอ่อนแล้วอบคืนตัวอีกครั้งในช่วงอุณหภูมิ 1400 ถึง 1600 °F [760 ถึง 870 °C]

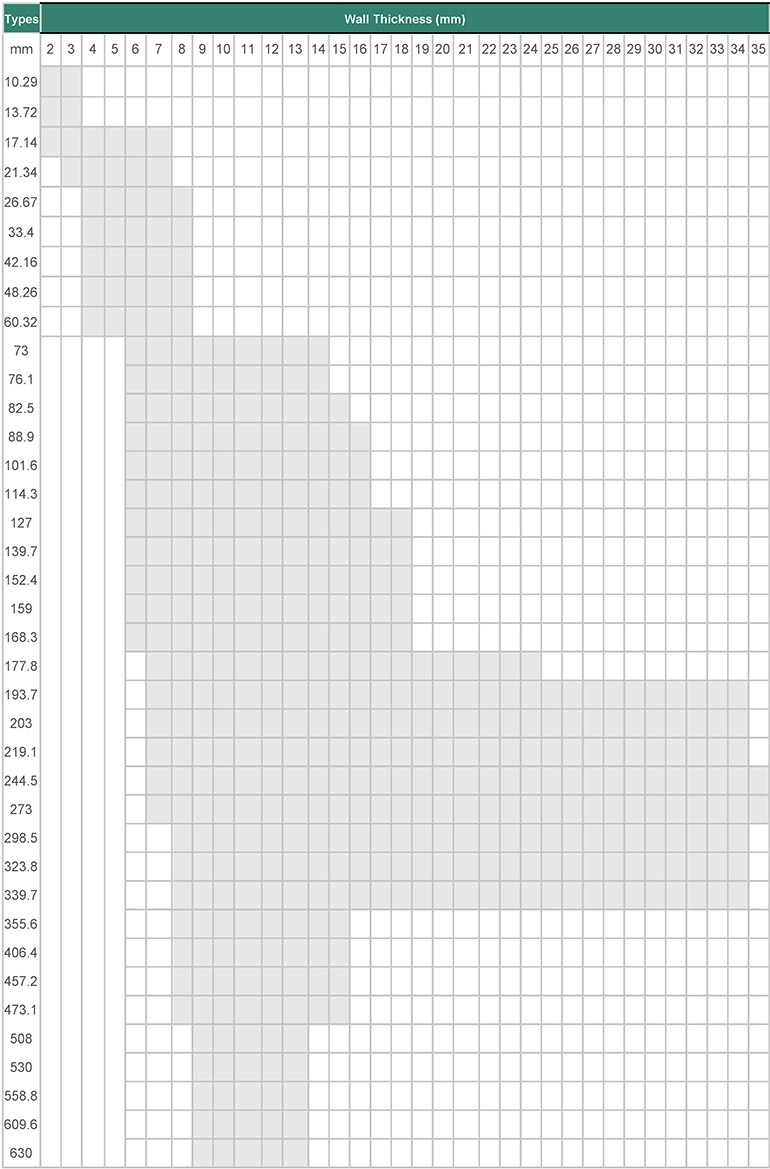

ตารางขนาดท่อเหล็ก ASTM A333

การใช้งานท่อเหล็ก ASTM A333

- ท่อส่งก๊าซธรรมชาติเหลว (LNG) อุณหภูมิต่ำ

- อุปกรณ์อุณหภูมิต่ำ

- หม้อไอน้ำแบบท่อไฟ

- หม้อไอน้ำแบบท่อน้ำ

- การต่อเรือ

- การก่อสร้าง

- เคมี

- ปิโตรเคมี

- การแปรรูปอาหาร

- การใช้งานในอุตสาหกรรมน้ำมันและก๊าซ และอุตสาหกรรมอื่นๆ

เราเป็นผู้ผลิตท่อหม้อไอน้ำและท่อโลหะผสมระดับมืออาชีพ เราจัดจำหน่ายท่อหม้อไอน้ำและท่อโลหะผสมขนาดต่างๆ รวมถึงท่อเหล็กและข้อต่อท่อที่มีคุณสมบัติหลากหลาย

ข้อได้เปรียบของเรา:

1. ผู้ให้บริการผลิตภัณฑ์และผู้ส่งออกท่อเหล็กชั้นนำของจีน

2. ราคาและคุณภาพที่แข่งขันได้จากโรงงานของเราเอง

3. การบูรณาการทรัพยากรแบบครบวงจร

4. ผ่านการรับรองมาตรฐาน ISO9001, CE และ SGS ทุกปี

5. บริการดีเยี่ยม ตอบกลับภายใน 24 ชั่วโมง

6. วิธีการชำระเงินที่ยืดหยุ่น

7. กำลังการผลิตที่แข็งแกร่ง

8. จัดส่งรวดเร็วและบรรจุภัณฑ์ส่งออกมาตรฐาน

9. OEM/ODM

หากคุณต้องการสอบถามข้อมูลเกี่ยวกับผลิตภัณฑ์เหล็กใดๆ โปรดติดต่อเราได้เลย:sales@bestartubes.com