ASTM A210 Tube

What is ASTM A210 Steel Tube?

ASTM A210 is the standard covers seamless medium-carbon steel boiler and superheater tubes. ASTM A210 also covers minimum wall thickness, tubing sizes, and boiler flues including safe ends, arch and stay tubes. ASTM A210 provides tensile and hardness properties but is only applicable to certain size limitations. Tubes shall be made by seamless process, marked as either hot-finished or cold-finished. The surface condition shall be specifically stated in the order.

Chemical Requirements for ASTM A210 Seamless Tubes

| Grade | C(Max) | Mn | Si(Min) | P(Max) | S(Max) |

| A1 | 0.27 | Max.0.93 | 0.10 | 0.035 | 0.035 |

| C | 0.35 | 0.29~1.06 | 0.10 | 0.035 | 0.035 |

Tensile Requirements for ASTM A210 Seamless Tubes

| Grade | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation (%) |

| A1 | ≥ 415 | ≥ 255 | ≥ 30 |

| C | ≥ 485 | ≥ 275 | ≥ 30 |

ASTM A210 / A210M Steel Tube Outside Diameter & Tolerance

| Pcorcess | Outside Diameter , mm | Tolerance, % |

| Hot rolled | OD≤101.6 | +0.4/-0.8 |

| 101.6<OD≤127 | +0.4/-1.2 | |

| Cold Drawn | OD<25.4 | ±0.10 |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤127 | +0.38/-0.64 | |

ASTM A213 / A210M Steel Tube Wall thickness & Tolerance

| Pcorcess | Outside Diameter , mm | Tolerance, % |

| Hot rolled | OD≤101.6, WT≤2.4 | +40/-0 |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | OD≤38.1 | +20/-0 |

| OD>38.1 | +22/-0 |

ASTM A210 / A210M Steel Tube Wall Thickness Tolerance

| Seamless, Cold-Finished Tubes | ||

| Outside Diameter In. (mm) |

Wall thickness Tolerance % | |

| Over (+) | Under (-) | |

| 1 ½ (38.1) and under | 20 | 0 |

| Over 1½ (38.1) | 22 | 0 |

ASTM A210 / A210M Steel Tube Outside Diameter Tolerance

| Cold-Finished Seamless Tubes | ||

| Outside Diameter In. (mm) |

Permissible Variations In. (mm) | |

| Over (+) | Under (-) | |

| Under 1 (25.4) | 0.004 (0.10) | 0.004 (0.10) |

| 1 to 1 ½ (25.4 to 38.1), Incl | 0.006 (0.15) | 0.006 (0.15) |

| Over 11⁄2 to 2 (38.1 to 50.8), Excl | 0.008 (0.20) | 0.008 (0.20) |

| 2 to 21⁄2 (50.8 to 63.5), Excl | 0.010 (0.25) | 0.010 (0.25) |

| 21⁄2 to 3 (63.5 to 76.2), Excl | 0.012 (0.30) | 0.012 (0.30) |

ASTM A210 / A210M Steel Tube Hydrostatic Test Pressures

Each tube shall be subjected to the hydrostatic pressure test, or instead of this test, a nondestructive test may be used when specified by the purchaser.

| Hydrostatic Test Pressures | |

| Outside Diameter of Tube, in. [mm] | Hydrostatic Test Pressure, psi [MPa] |

| Under 1 [25.4] | 1000 [7] |

| 1 to 11⁄2 [25.4 to 38.1], excl | 1500 [10] |

| 11⁄2 to 2 [38.1 to 50.8], excl | 2000 [14] |

| 2 to 3 [50.8 to 76.2], excl | 2500 [17] |

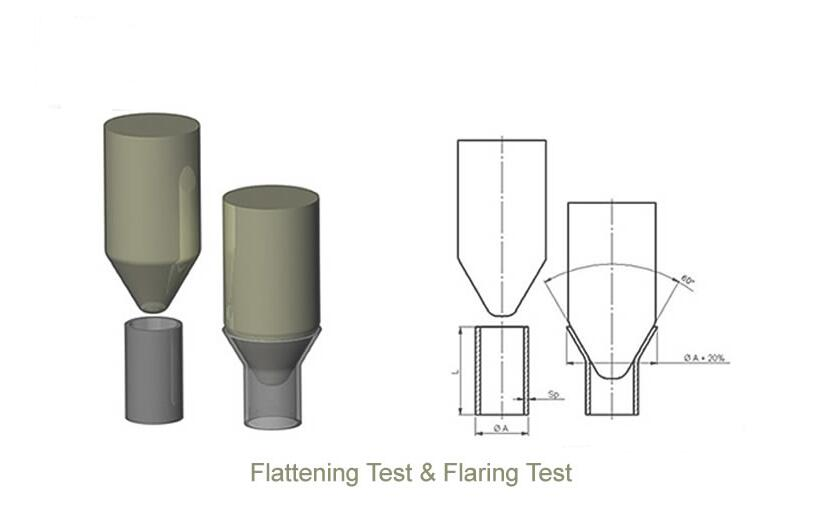

ASTM A210 / A210M Steel Tube Flattening Test

One flattening test shall be made on specimens from each end of one finished tube from each lot, but not the one used for the flaring test. Tears or breaks occur at the 12 or 6 o’clock positions on Grade C tubing with sizes of 2.375 in. [60.3 mm] in outside diameter and smaller shall not be considered a basis for rejection. One flaring test shall be made on species-men from each end of the one finished tube from each lot, but not the one used for the flattening test.

ASTM A210 / A210M Steel Tube Flaring Test

One flaring test shall be made on species-men from each end of the one finished tube from each lot, but not the one used for the flattening test.

Size Chart of ASTM A210 Steel Tube

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Application of ASTM A210 Steel Tube

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipement

- Offshore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Chemical Equipment

- Sea Water Equipement

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

We are a professional Boiler And Alloy Tube manufacturer. We provide Boiler And Alloy Tube of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com