Drill Pipe

What is the drill pipe?

A drill pipe is a hardwearing seamless pipe that is rotated to circulate the drilling fluid. This pipe is useful for pumping back the drilling fluid back up the annulus. The annulus is the space in the oil well between the casing and the piping. Easy circulation of the fluid within the well is possible because of the Annulus. The drill pipe is subject to axial tension since high torque is required for rotating the down-hole assembly drilling the fluid and circulating it. The OCTG drill pipe needs to be extremely strong as they have to bear a high amount of stress underground. The drill pipe is used at the drilling rigs and they are available in different sizes and different qualities. OCTG drill pipe needs to be sturdy and meet the standards of API 5DP and API SPEC 7-1.

Chemical Composition of Drill Pipe(%)

|

Grade |

Chemical composition |

|

|

P |

S |

|

|

E75 |

<0.015 |

<0.003 |

|

X95 |

<0.015 |

<0.003 |

|

G105 |

<0.015 |

<0.003 |

|

S135 |

<0.015 |

<0.003 |

|

Tool joint |

<0.015 |

<0.003 |

Mechanical Properties of Drill Pipe

| Pipe body | Grade | Yield strength | Tensile strength | Elongation | Hardness | Full-size Charpy impact test(J) | ||||||

| min | max | min | min | |||||||||

| Psi | MPa | Psi | MPa | Psi | MPa | HBW | HRC | Average | Single | |||

| E75 | 75000 | 517 | 105000 | 724 | 100000 | 689 | 625000A

0.2/U0.9 |

- | - | 80 | 65 | |

| X95 | 95000 | 655 | 125000 | 862 | 105000 | 724 | - | - | 80 | 65 | ||

| G105 | 105000 | 724 | 135000 | 931 | 115000 | 793 | - | - | 80 | 65 | ||

| S135 | 135000 | 931 | 165000 | 1138 | 145000 | 1000 | - | - | 80 | 65 | ||

| Weld zone | Tool joint | 120000 | 827.4 | - | - | 140000 | 965.3 | 0.13 | 285 | - | 80 | 65 |

| E75 | 75000 | 517 | - | - | 100000 | 689 | - | ?37 | 40 | 27 | ||

| X95 | 88000 | 609 | - | - | 103000 | 712 | - | ?37 | 40 | 27 | ||

| G105 | 95000 | 655 | - | - | 105000 | 724 | - | ?37 | 40 | 27 | ||

| S135 | 105000 | 724 | - | - | 115000 | ?37 | 40 | 27 | ||||

Drill Collars are integral heavy-wall joints that are manufactured from a solid bar of modified alloy steel. The solid bars are quenched and tempered to obtain the required mechanical properties, then trepanned, drifted, and threaded. Drill collars are furnished as slick or spiraled in 30 or 31-foot lengths.

Slick drill collars are supplied with the mill as-rolled surface finish. Spiraled drill collars have grooves machined on the outside surface. The spiral grooves promote an even flow of drilling fluid around the collar diameter, equalizing pressure and reducing the occurrence of differential sticking.

Connection of Drill Pipe

Tubing drill pipe ensure thread connections of various kinds including the following categories,

•Integral connections

•Extreme line

•Integral thread seal connections

•VAM premium connections

•Integral metal seal connections

•Coupled connections

•BTC

•API (STC and LTC)

•Threaded connections

Types of Drill Pipe

Standard drill pipes are long tubular sections of pipe that make up the majority of the drill string. They are typically a 31-foot-long section of tubular pipe but may be anywhere from 18 to 45 feet in length.

Heavy-weight drill pipe (HWDP) is a tubular pipe that adds weight or acts as a transitional piece in the drill string. As a transitional section of the drill string, it is placed between the drill collar and the standard drill pipe to reduce fatigue failures. In other applications, the HWDP is used as an additional weight to weigh down the drill string.

Drill collars are a component of the drill string that makes up part of the BHA. They are thicker-walled, heavier, and more rigid than drill pipes and are primarily used to weigh down the drill bit while dampening vibration and impact forces.

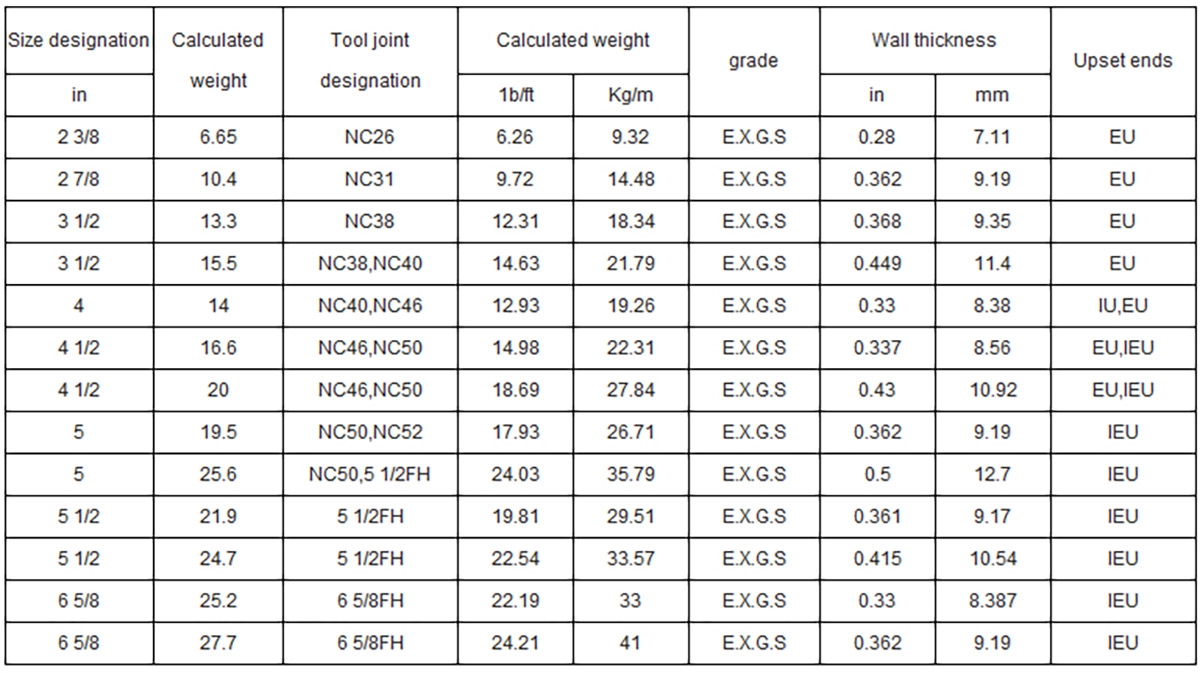

Size Chart of Drill Pipe

Application of Dirll Pipe

Oil drill pipe is widely used in oil exploration, oil production, seismic exploration, geological research and cement reinforcement of well wall and other fields. Especially in the field of oil exploration, oil drill pipe is one of the indispensable tools.In short, oil drill pipe is a very important petroleum engineering tool, it can help human explore the potential of oil and other resources, improve the output of resources, and make important contributions to economic and social development.

We are a professional Drill Pipemanufacturer. We provide Drill Pipe of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com