ASTM A213 Pipe

What is ASTM A213 Steel Pipe?

ASTM A213 tubing is seamless ferritic steel and austennitic alloy SS (stainless steel) tubing used in boilers for super heaters, and heat exchangers.

ASTM A213/ASME SA213 covers low alloy steel pipes and minimum-wall-thickness, seamless ferritic and austenitic steel, boiler and super-heater tubes and austenitic steel heat-exchanger tubes, designated Grades TP304,TP304H,TP304L,TP310S, TP310HCbN, TP316, TP316H, TP316L etc.

Dimension

|

Group |

Grade |

Type |

Total elongation under load % |

Yield strength Mpa |

Tensile strength min MPa |

Hardness max |

||

|

min |

max |

HRC |

HBW |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

1 |

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

2 |

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

C90 |

|

0.5 |

621 |

724 |

689 |

25.4 |

255 |

|

|

C95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

|

|

T95 |

|

0.5 |

655 |

758 |

724 |

25.4 |

255 |

|

|

3 |

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

|

4 |

Q125 |

All |

0.65 |

862 |

1034 |

931 |

- |

-

|

Mechanical Properties

| Label | D Outside diameter mm | Wall thickness t mm | C Type of end-finish | |||||||||

| 1 | 2 | H40 | J55 | L80 | N80 1Q | C90 | T95 | P110 | ||||

| NU T&C | EU T&C | IJ | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.9 | 2.75 | 2.9 | 2.76 | 48.26 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | - |

| 1.9 | 3.65 | 3.73 | - | 48.26 | 5.08 | PU | PU | PU | PU | PU | PU | PU |

| 1.9 | 4.42 | - | - | 48.26 | 6.35 | - | - | P | - | P | P | - |

| 2.375 | 4 | - | - | 60.32 | 4.24 | PU | PN | PN | PN | PN | PN | - |

| 2.375 | 4.6 | 4.7 | - | 60.32 | 4.83 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2.375 | 5.8 | 5.95 | - | 60.32 | 6.45 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2.375 | 6.6 | - | - | 60.32 | 7.49 | - | - | P | - | P | P | - |

| 2.375 | 7.35 | 7.45 | - | 60.32 | 8.53 | - | - | PU | - | PU | PU | - |

| 2.875 | 6.4 | 6.5 | - | 73.02 | 5.51 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2.875 | 7.8 | 7.9 | - | 73.02 | 7.01 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2.875 | 8.6 | 8.7 | - | 73.02 | 7.82 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2.875 | 9.35 | 9.45 | - | 73.02 | 8.64 | - | - | PU | - | PU | PU | - |

| 2.875 | 10.5 | - | - | 73.02 | 9.96 | - | - | P | - | P | P | - |

| 3.5 | 7.7 | - | - | 88.9 | 5.49 | PN | PN | PN | PN | PN | PN | - |

| 3.5 | 9.2 | 9.3 | - | 88.9 | 6.45 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 3.5 | 10.2 | - | - | 88.9 | 7.34 | PN | PN | PN | PN | PN | PN | - |

| 3.5 | 12.7 | 12.95 | - | 88.9 | 9.52 | - | - | PNU | PNU | PNU | PNU | PNU |

| 3.5 | 14.3 | - | - | 88.9 | 10.92 | - | - | P | - | P | P | - |

| 3.5 | 15.5 | - | - | 88.9 | 12.09 | - | - | P | - | P | P | - |

| 4 | 9.5 | - | - | 101.6 | 5.74 | PN | PN | PN | PN | PN | PN | - |

| 4 | 10.7 | 11 | - | 101.6 | 6.65 | PU | PU | PU | PU | PU | PU | - |

| 4 | 13.2 | - | - | 101.6 | 8.38 | - | - | P | - | P | P | - |

| 4 | 16.1 | - | - | 101.6 | 10.54 | - | - | P | - | P | P | - |

| 4.5 | 12.6 | 12.75 | - | 114.3 | 6.88 | PNU | PNU | PNU | PNU | PNU | PNU | - |

| 4.5 | 15.2 | - | - | 114.3 | 8.56 | - | - | P | - | P | P | - |

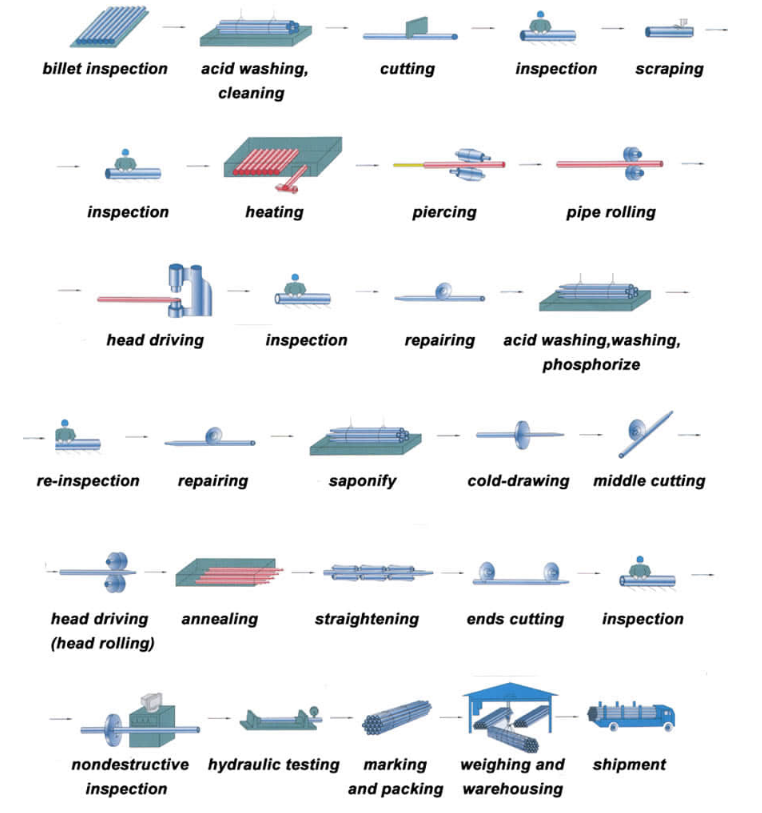

Production Process

Manufacturing process of ASTM A213 Seamless Steel Pipe

Application of ASTM A213 Steel Pipe

- Chemical Industry

- Paper Industry

- Fertilizer Industry

- Fabric Industry

- Aviation Industry

- Nuclear Industry

- Fluid Industry

- Gas and Oil Industry

- Heat Transmission Industry

- Pressure Service

- Construction and Ornamental

- Boilers and Heat exchangers

- Auto Parts

- Medical Device

- Food Industry

- Building Materials

We are a professional Stainless Steel Pipe manufacturer. We provide Stainless Steel Pipe of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com