Steel Coil

What is a Steel Coil?

Steel coil is made from a finished steel product such as sheet or strip that has been wound or coiled after rolling; its width is much greater than the thickness. Depending on the production method, steel coil can be classified as Hot Rolled, Cold Rolled, or Galvanized.

When time is of the essence, it can be challenging to find the exact product that you need. Regardless of the size or the type of steel coil, we guarantee our high-quality products fit your custom application and adherence to ISO 9001 2015 accreditation. Our steel materials are sourced from mills with the highest regard for reputation and quality. For a decade, our success has derived from our continuous growing reputation of providing products that exceed professional demands.

Stainless Steel Coils Mechanical Properties

| Grade | Standard | Yield Strength Rp0.2 (N/mm²) |

Tensile Strength Rm (N/mm²) |

Elongation % | Hardness (HV) |

Hardness (HRB) |

|---|---|---|---|---|---|---|

| 201 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 35 | ≤ 260 | ≤ 101 |

| 202 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 40 | ≤ 218 | ≤ 95 |

| 2205 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 293 | ≤ 30 |

| 2507 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 290 | ≤ 30 |

| 253 MA® | ASTM | ≥ 310 | ≥ 600 | ≥ 40 | ≤ 217 | ≤ 95 |

| 254 SMO® | ASTM | ≥ 300 | ≥ 650 | ≥ 35 | ≤ 223 | ≤ 96 |

| 301 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 304 | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 210 | ≤ 92 |

| 304L | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 309S | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 310S | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316L | ASTM A240 | ≥ 177 | ≥ 480 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316Ti | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 317L | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 321 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 347 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 35 | ≤ 200 | ≤ 90 |

| 410S | ASTM A240 | ≥ 205 | ≥ 440 | ≥ 20 | ≤ 210 | ≤ 92 |

| 420J2 | ASTM A240 | ≥ 225 | ≥ 540 | ≥ 18 | ≤ 180 | ≤ 80 |

| 430 | ASTM A240 | ≥ 206 | ≥ 450 | ≥ 22 | ≤ 200 | ≤ 88 |

| 654 SMO® | ASTM | ≥ 430 | ≥ 750 | ≥ 40 | ≤ 250 | ≤ 100 |

| 904L | ASTM | ≥ 216 | ≥ 490 | ≥ 35 | - | ≤ 90 |

| UNS N08926 | ASTM | ≥ 295 | ≥ 650 | ≥ 35 | - | ≤ 100 |

| UNS S17400 | ASTM | ≥ 725 | ≥ 930 | ≥ 10 | - | - |

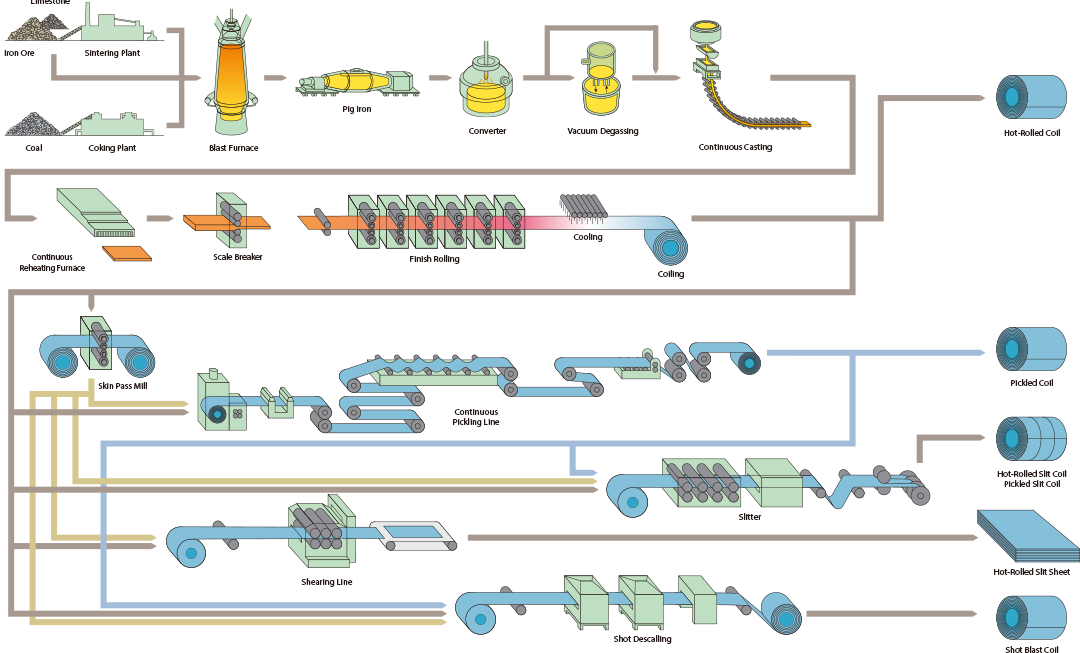

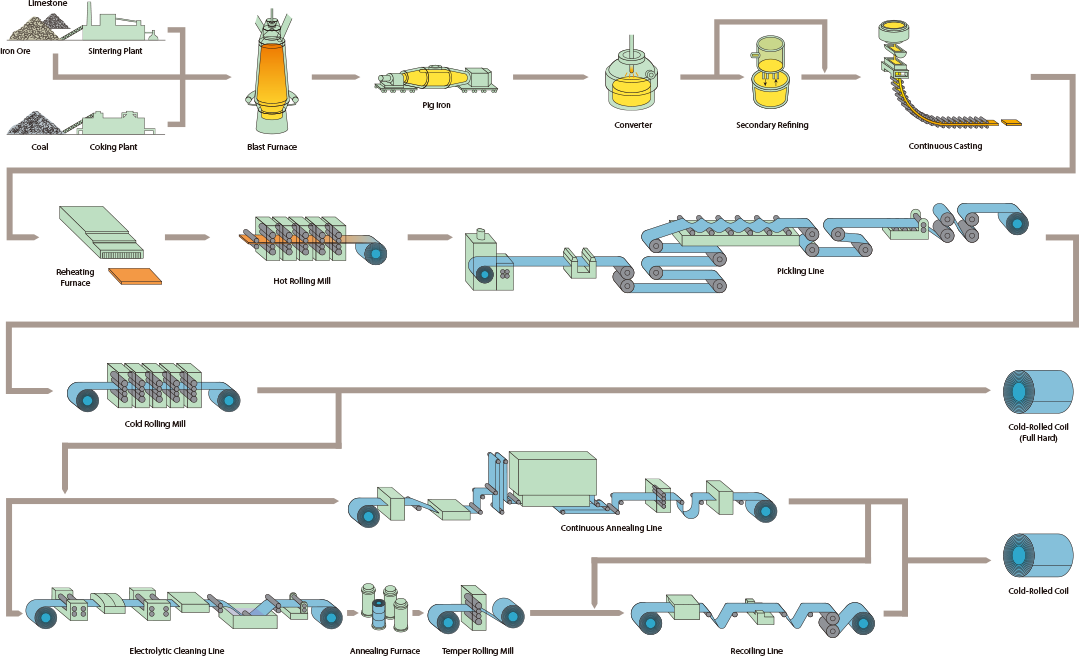

Steel Coil Production

Steel coil is finished steel sheet or strip that has been coiled or wound after rolling with the width of the metal sheet being greater than its thickness. Steel coil with certain coatings can be weather-resistant, protect against moisture, and is ecofriendly. Steel coil is produced through different processes depending on the desired outcome.

Hot-rolled steel coil is steel plate that is rolled at a high temperature, making the steel easier to manipulate. Due to the quick and easy process, hot-rolled steel saves time and is less expensive to manufacture.

Cold-rolled steel coil has a nicer finish and is more durable than hot-rolled steel. Cold-rolling is a process where the steel is rolled at room temperature, below its recrystallization temperature. While cold-rolled steel coil is more superior to other coils, cold-rolled steel can be harder to manipulate due to the higher carbon content.

Galvanized steel coil is created through a hot-dipped process that dips the metal into zinc for a nice smooth coating. The coating creates a strong rust resistance and prolongs the life of the steel coils.

Stainless steel coils are divided into austenite, ferrite, martensite, dual-phase (ferrite-austenite) cold rolled coils, and hot-rolled coils. In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation, and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo annealing, solution treatment, aging treatment, and other heat treatments before delivery.

Hot-Rolled Steel Coils Manufacturing Processes

Cold-Rolled Steel Coils Manufacturing Processes

Stainless Steel Coils Applications

Stainless steel coils applications ranges from industrial sectors to household appliances. In the following, we will take a look at some of the most prevalent uses of stainless steel coils:

Construction and Construction byproducts

Electrical and Electronic Industry

Food and Beverage Industry

Medical and Surgical Equipment

Automotive Industry

We are a professional Steel Coil manufacturer. We provide Steel Coil of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com