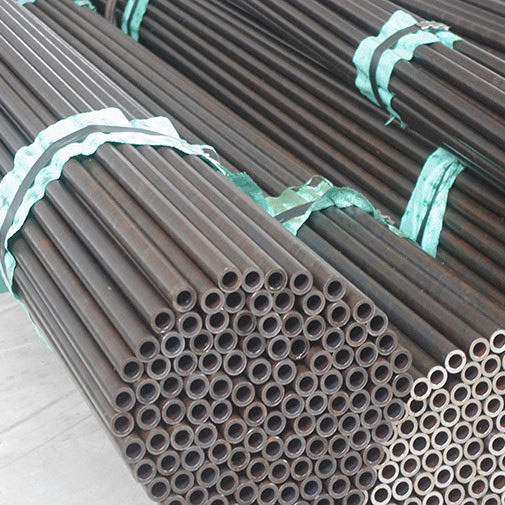

ASTM A335 Tube

What is ASTM A335 Steel Pipe?

ASTM A335 steel pipe (or ASME SA335 steel pipe) is the standard specification for seamless ferritic alloy steel pipe for high-temperature service. It covers steel grades from P1 to P5, P9, P11, P12, P91. Grades P11/P22 and P91/92 pipes are commonly used in power generation and petrochemical industries. ASTM A335 grade P5 and P9 pipes are mostly used for application in the petrochemical industry. Not only to power generation and petrochemical industries, it is also applied to gas processing equipment, oil serves, heaters/reheat lines, and boilers.

Features of ASTM A335 Steel Pipe

● Strong resistance to rupturing at high temperatures and high pressures

● May be used for Hydrogen Sulfide Corrosion Services

● Resistant to cracking from hydrogen attack and embrittlement

● Resistant to hot sulfide corrosion cracking

● Can be used for NACE Applications where sour environments are under high temp and pressure

● Can be used in NACE-MRO 175 Sour Service

● Ideal for creep rupture applications

● Can handle high temperatures with very low elasticity

Chemical And Mechanical Properties of ASTM A335 Steel Pipe

|

Material |

C |

Si |

Mn |

P |

S |

Mo |

Cr |

|

% |

% |

% |

% |

Max |

% |

% |

|

|

A335 Grade P1 |

0.10---0.20 |

0.10---0.50 |

0.30---0.80 |

0.025 |

0.025 |

0.44-0.65 |

/ |

|

A335 Grade P5 |

Max 0.15 |

Max 0.50 |

0.30---0.60 |

0.025 |

0.025 |

0.45-0.65 |

4.00-6.00 |

|

A335 Grade P9 |

Max 0.15 |

0.25-1.00 |

0.30---0.60 |

0.025 |

0.025 |

0.90-1.10 |

8.00-10.00 |

|

A335 Grade P11 |

0.05---0.15 |

0.5---1.0 |

0.30---0.60 |

0.025 |

0.025 |

0.45-0.65 |

1.00-1.50 |

|

A335 Grade P12 |

0.05---0.15 |

Max 0.50 |

0.30---0.61 |

0.025 |

0.025 |

0.45-0.65 |

0.80-1.25 |

|

A335 Grade P22 |

0.05---0.15 |

Max 0.50 |

0.30---0.60 |

0.025 |

0.025 |

0.87-1.13 |

1.90-2.60 |

|

A335 Grade P91 |

0.08-0.12 |

0.20-0.50 |

0.30---0.60 |

0.020 |

0.010 |

0.85-1.05 |

8.00-9.50 |

|

A335 Grade P92 |

0.07-0.13 |

Max 0.50 |

0.30---0.60 |

0.020 |

0.010 |

0.30-0.60 |

8.50-9.50 |

| Mechanical Property | P1,P2 | P12 | P91 | P92 | P122 | Others |

| Tensile strength ksi | 55 | 60 | 85 | 90 | 90 | 60 |

| Tensile strength mpa | 380 | 415 | 585 | 620 | 620 | 415 |

| Yield strength ksi | 30 | 32 | 60 | 64 | 58 | 30 |

| Yield strength mpa | 205 | 220 | 415 | 440 | 400 | 205 |

| Calculated minimum elongation values | ||||

| Elongation in 2in or 50mm, min% | ||||

| Wall thickness | P5,P9,P11,P22 | P91 | ||

| in | mm | Longitudinal | Transverse | Longitudinal |

|

5/16 (0.312) |

8 |

30 |

20 |

20 |

|

9/32 (0.281) |

7.2 |

28 |

19 |

19 |

|

1/4 (0.250) |

6.4 |

27 |

18 |

18 |

|

7/32 (0.219) |

5.6 |

26 |

/ |

17 |

|

3/16 (0.188) |

4.8 |

24 |

/ |

16 |

|

5/32 (0.156) |

4 |

22 |

/ |

15 |

|

7/8 (0.125) |

3.2 |

21 |

/ |

14 |

|

3/32 (0.094) |

2.4 |

20 |

/ |

13 |

|

1/18 (0.062) |

1.6 |

18 |

/ |

12 |

|

5/16 (0.312) |

8 |

30 |

20 |

20 |

| NPS(DN) Designator | Over | Under | ||

| in | mm | in | mm | |

|

1/8 to 1 1/2 [6 to 40], incl. |

1/64 (0.015) |

0.40 |

1/64 (0.015) |

0.40 |

|

Over 1 1/2 to 4 [40 to 100], incl. |

1/32 (0.031) |

0.79 |

1/32 (0.031) |

0.79 |

|

Over 4 to 8 [100 to 200], incl. |

1/16 (0.062) |

1.59 |

1/32 (0.031) |

0.79 |

|

Over 8 to 12 [200 to 300], incl. |

3/32 (0.093) |

2.38 |

1/32 (0.031) |

0.79 |

| Over 12 (300) | +/-1% of the specified outer diameter | |||

| NPS(DN) Designator | Tolerance, % from Specified | |

|

1/8 to 2 1/2 [6 to 65] incl., all t/D ratios |

20.0% |

12.5% |

|

Above 2 1/2 [65], t/D < or = 5% |

22.5% |

12.5% |

|

Above 2 1/2 [65], t/D > 5% |

15.0% |

12.5% |

|

1/8 to 2 1/2 [6 to 65] incl., all t/D ratios |

20.0% |

12.5% |

| (t = Specified Wall Thickness; D = Specified Outside Diameter) | ||

|

ASTM A335 Steel Pipe Grade |

Heat Treatment Type |

Normalizing Temperature Range F [C] |

Subcritical Annealing or Tempering |

|

P5 |

Full or Isothermal Anneal |

||

|

P5 b |

Normalize and Temper |

- |

1250 [675] |

|

P5 c |

Subcritical Anneal (P5c only) |

- |

1325 - 1375 [715 - 745] |

|

P9

|

Full or Isothermal Anneal |

||

|

Normalize and Temper |

- |

1250 [675] |

|

|

P11

|

Full or Isothermal Anneal |

||

|

Normalize and Temper |

- |

1200 [650] |

|

|

P22

|

Full or Isothermal Anneal |

||

|

Normalize and Temper |

- |

1250 [675] |

|

|

P91

|

Normalize and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

|

Quench and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

Inspection And Test Performed of ASTM A335 Steel Pipe

Chemical composition inspection, mechanical properties test ( Tensile strength, yield strength, elongation,Flattening, Hardness, or bend test) Surface and dimension test, Non-destructive test, Hydrostatic Test.

Packing and Delivery of ASTM A335 Steel Pipe

Size Chart of ASTM A335 Steel Pipe

Diameter of ASTM A335 Steel Pipe

| A335 Steel Pipe | Over | Under | ||

| NPS [DN] | in. | mm | in. | mm |

| 1/8 to 1 1/2 / DN 6 to 40 | 1/64 (0.015) | 0.4 | 1/64 (0.015) | 0.4 |

| Over 1 1/2 to 4 / DN 40 to 100 | 1/32 (0.031) | 0.79 | 1/32 (0.031) | 0.79 |

| Over 4 to 8 / DN 100 to 200 | 1/16 (0.062) | 1.59 | 1/32 (0.031) | 0.79 |

| Over 8 to 12 / DN 200 to 300 | 3/32 (0.093) | 2.38 | 1/32 (0.031) | 0.79 |

| Over 12 / > DN 300 | +/- 1% of the specified outside diameter | |||

Wall Thickness of ASTM A335 Steel Pipe

The tolerances in WT, in %, from specified are:

- 1/8 to 2 1/2 [6 to 65] incl., all t/D ratios: over 20%, under 12.5%

- Above 2 1/2 [65], t/D < or = 5%: over 22.5%, under 12.5%

- Above 2 1/2 [65], t/D > 5%: over 15%, under 12.5%

t = Specified Wall Thickness; D = Specified Outside Diameter)

Application of ASTM A335 Steel Pipe

- Refinery

- Machine building

- Oil and gas

- Power generation

- Gas processing

- Fertilizer

- Sugar

- Gas processing equipment

- Oil serves

- Heaters/reheat lines

- Boilers

- Power generation

- Petrochemical industries

We are a professional Boiler And Alloy Tube manufacturer. We provide Boiler And Alloy Tube of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com