Company News

-

Tube Dusseldorf & Bestar steel co., ltd

Exhibition name Tube Dusseldorf Time April 15th-19th ,2024 Location Dusseldorf Exhibition Center, Germany Bestar Steel Booth No. C10-4, Hall 7.1 The Tube: The world's leading trade fair for the tube...Read more -

ADIPEC EXHIBITION AND CONFERENCE 2023

Exhibition name Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC 2023) Time 2nd – 5th October 2023 Location UAE Booth 13791 ADIPEC is the world's largest and most inclusive gathering for the energy ind...Read more -

30 years anniversary activity in Bestar Steel

30 years anniversary activity in Bestar Steel. Here is the first part in Beijing. to be continued. Here is the part of our member in the Beijing station. For the next part, we wait and see more activities.Read more -

The purpose of preheating the steel pipe before welding the spiral steel pipe

Critical components of alloy steel and thick parts must be preheated before welding. The purpose of preheating the spiral steel pipe before welding is as follows: (1) Preheating can slow down the cooling rate after welding, make hydrogen diffuse in the weld metal and escape, a...Read more -

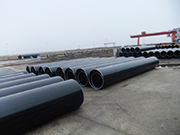

Advantages and disadvantages of spiral steel pipe

Advantages of spiral steel pipe: (1) Steel pipes of different diameters can be produced by using strip steel of the same width, especially steel pipes of large diameter can be produced by narrow strip steel. (2) Under the same pressure conditions, the stress of the spiral stee...Read more -

Distinguishing method of welded steel pipe and seamless steel pipe

1. Metallographic method The metallographic method is the main method to distinguish welded steel pipes and seamless steel pipes. There is no welding material added to the high-frequency resistance welded steel pipe, so the weld seam in the welded steel pipe is very narrow, an...Read more -

Introduction to Common Methods of Steel Pipe Welding

At present, the commonly used methods for welding steel pipes are electrode arc welding (SMAW), submerged arc welding (SAW), gas tungsten arc welding (GTAW), gas melting arc welding (GMAW), flux cored arc welding (FCAW) and Downward welding and so on. (1) The advantages of ele...Read more -

What are the heat treatment methods for spiral steel pipes

1. Thermomechanical treatment High-temperature thermomechanical treatment can improve the yield ratio and elastic limit of spiral steel pipe. Improve the comprehensive mechanical properties, fatigue properties, and stress relaxation properties of the spiral steel pipe. Reducin...Read more -

The difference and use of seamless steel pipe and spiral welded pipe

Seamless steel pipes are widely used. General-purpose seamless steel pipes are rolled from ordinary carbon structural steel, low-alloy structural steel, or alloy structural steel, with the largest output, and are mainly used as pipelines or structural parts for conveying fluid...Read more