News

-

Manufacturing Technology of Large Diameter Longitudinal Submerged Arc Welded Steel Pipe

The large-diameter straight seam submerged arc steel pipe is mainly responsible for the pipeline transportation of marine and land oil and gas, oil and natural gas, coal and mineral paddles, etc. It is especially suitable for the “West-East Gas Pipeline” project cu...Read more -

The purpose of preheating the pipe before welding the spiral steel pipe

The purpose of preheating the spiral steel pipe before welding is as follows: (1) Preheating can slow down the cooling rate after welding so that hydrogen diffuses in the weld metal and escapes to avoid cracking caused by hydrogen. It can also reduce the degree of hardening of...Read more -

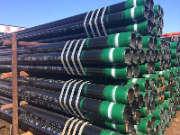

Anti-corrosion Countermeasures for Oil Casing

1. First of all, do a good job of water quality standards, and strictly monitor and manage water quality. Implement cleaning and separate injection, strengthen the cleaning of the main water pipeline, ensure that the water quality in the station and the bottom of the well meet...Read more -

How to improve the stability of spiral seam submerged arc welded steel pipe in the warehouse

With spiral seam submerged arc welded steel pipe in the warehouse, the spiral steel pipe quality become a problem for us. How improve the stability of spiral seam submerged arc welded steel pipe in the warehouse become more and more important. 1) Dimensions of steel wire, reba...Read more -

How to solve the deformation problem of spiral seam submerged arc welded steel pipe

The spiral seam submerged arc welded steel pipe rotates and starts to enter the soft formation. Under the action of the tri-cone, the drill bit first produces elastic shear deformation of the formation, and then it is removed under the pressure of the tri-cone. In the simulate...Read more -

The high-frequency welding process of submerged arc steel pipe

Introduction of the high-frequency welding process of submerged arc steel pipe: 1. Control of weld gap: After rolling by multiple rollers, the strip is sent to the welded pipe unit. The strip steel is gradually rolled up to form a circular tube blank with an opening gap, and t...Read more -

Practical advantages and diameter expansion technology of straight seam steel pipe

In a sense, straight seam steel pipe is a welding process of steel pipe opposite to spiral steel pipe. The welding of straight seam steel pipes is relatively common in the market due to the relatively simple process and low welding cost, which can achieve high efficiency durin...Read more -

What is the difference between 2205 duplex stainless steel pipe and 304 stainless steel pipe

1. Compared with 304 stainless steel pipe, the advantages of duplex stainless steel pipe are as follows: (1) The yield strength is more than double that of ordinary austenitic stainless steel, and it has sufficient plastic toughness required for forming. The wall thickness of ...Read more -

What is the difference between spiral steel pipe and steel coil pipe

Both spiral steel pipes and steel coiled pipes belong to welded steel pipes, and the production processes of the two are very different. Spiral steel pipe is a spiral seam steel pipe made of strip steel coil as raw material, often warmly extruded, and welded by the automatic d...Read more