Product Information

-

The uses and applications of alloy steel T11 tube

Alloy steel T11 tube are available in highest quality and grade also in various dimensions. Alloy steel T11 tube are available with international quality parameters. For the production of these tube, companies follow the strict guidance mentioned in manual. Alloy steel T11 tub...Read more -

The Spiral Welded Pipe Manufacturing Process

Steel strip coil, welding wire, and flux are the raw ingredients. Before being used, it must pass stringent physical and chemical tests. After the steel pipe is rolled, use automatic submerged arc welding to repair welding using single wire or double wire submerged arc weldin...Read more -

Common Surface Defects of Welded Steel Pipe

(1) Layered steel Layered wall steel pipe means that the cross section is divided into two layers, and the exposed steel plate surface presents vertical cracks in layers. Some of the internal and external surfaces of the display steel are locally depressed or bulged, and the d...Read more -

What is the difference between aisi and astm standards

Today, the formation of various systems make use of components that are manufactured all over the world. Global import export for metal components has been on a steady rise. And with each passing day, manufacturers across the world offer competitive prices, lead times, and min...Read more -

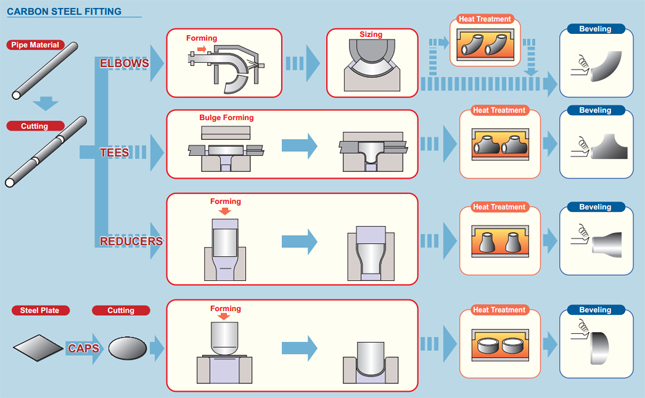

Butt-Welding Fitting Manufacturing Processes

Elbow Manufacturing Process a. Mandrel Method/Hot Forming Method One of the most common manufacturing methods for manufacturing Elbows from pipes. After heating the raw material, it is pushed over a die called “mandrel” which allows the pipe to expand and bend simultaneously. ...Read more -

ERW vs Spiral Pipes: What Are the Differences?

Both ERW Carbon Steel pipes and Spiral Pipes are used to transport oil, gas, and chemicals. They have similar utilities and applications. However, when you look further into their workings, one can find differences in various aspects. If looked into closely, one can point out ...Read more -

The difference between carbon steel VS cast steel

1. Different in nature Cast steel: Cast steel is a kind of casting alloy. Iron and carbon are the main elements. The carbon content is between 0-2%. Carbon steel: Carbon steel is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. Generally, it also contains a smal...Read more -

Types of Hollow Structural Sections

Hollow structural sections typically come in three main forms: rectangular hollow sections (RHS), square hollow sections (SHS) and circular hollow sections (CHS). Each type of hollow section has its benefits, properties, and purposes. Circular Hollow Sections The circular holl...Read more -

Hot-finished vs. cold-formed tubes

Electric Resistance welded (ERW) carbon steel tubes have been successfully used in building and industrial pipework installations for many years. However, we are now seeing the increasing use of imported, commodity welded tubes that may prove to be less suitable for typical pi...Read more