Product Information

-

Types and uses of welded steel pipes

1. Welded steel pipe for low-pressure fluid transportation is also called a general welded pipe, commonly known as clarinet. It is a welded steel pipe for conveying water, gas, air, oil and heating steam, and other generally lower pressure fluids and other purposes. 2. Galvani...Read more -

Basic requirements for the appearance of welds of straight seam steel pipes

1. The surface of the welding joint: A. Cracks, lack of fusion, pores, slag inclusion, and splashes are not allowed. B. The weld surface of pipes whose design temperature is lower than -29 degrees, stainless steel and alloy steel pipes with a greater tendency to hardening shal...Read more -

Five types of annealing methods in the steel pipe

1. Fully annealed Process: Heat the steel to 20~30℃ above Ac3, cool it slowly (with the furnace) after holding it for some time to obtain a heat treatment process (complete austenitization) close to the equilibrium structure. Complete annealing is mainly used for hypereutectoi...Read more -

How to determine the material of straight seam steel pipe

For the straight seam steel pipe, the material should belong to a steel product with a wide range of use frequency. It has a wide range of applications in engineering construction and equipment production! With the continuous improvement of market technology, the production pr...Read more -

Straight seam steel pipes procurement method and processing method

Straight seam steel pipe procurement method: 1. Purchasing needs to understand the types of steel pipes 1) Divided by type: straight seam steel pipe, seamless steel pipe, spiral steel pipe, etc. 2) Classification of cross-section shapes of straight seam steel pipes: square pip...Read more -

How to install galvanized steel pipe

First. According to the specific conditions of the diameter and pipeline, select the appropriate connection method 1. Welding: enter the installation at an appropriate time according to the progress of the site. Fix the bracket in advance, draw a sketch according to the actual...Read more -

Key points of internal thread tapping of stainless steel pipe fittings

1 Tap design and manufacture in the steel pipe fitting a. Choose a better tap material. Adding special alloy elements to ordinary high-speed tool steel can significantly improve the wear resistance and toughness of the tap. b. Coating titanium nitride coating into the surface ...Read more -

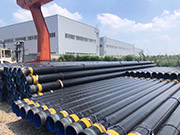

How to transport 3PE anti-corrosion steel pipes to ensure that the anti-corrosion layer is not damaged

3PE anti-corrosion steel pipe is a high-level anti-corrosion steel pipe. It is composed of three layers of anti-corrosion: primer + glue + PE. It has high corrosion resistance and wear resistance. The normal service life is about 30 years, mainly due to the quality of its anti...Read more -

The role of heat treatment of stainless steel pipe fittings

After stainless steel pipe fittings are processed by processes such as forming and welding, the metal molecular structure, magnetic properties, and physical properties change. The atmosphere-protected solid solution process can restore the corrosion resistance affected after p...Read more