News

-

Transportation of steel pipe – which method is best?

Are you looking to transport steel pipe to your project site or inventory location? This post will discuss transportation of steel pipe and help you determine which method will work best. There are three ways to transport your material; barge, truck and rail. Three key factors...Read more -

What Is ASME Standard Flanges And Its Application Industries

ASME Standard Flanges refers to a series of specifications for the production of flange products based on ASME Boiler and Pressure Vessel Code and ASME Pipe Codes, by specifying the flange size, surface conditions of the flange joint faces, sealing surface shape, pressure/temp...Read more -

All You Need To Know About Stainless Steel 304 Pipes and Tubes

Stainless Steel 304 is one of the most flexible and commonly used stainless steels on the market, and 304 Stainless Steel is the most commercially used stainless steel alloy of its kind. SS 304 is basically an austenitic chromium alloy that is also known as “18/8” stainless as...Read more -

What is ss coil? What is stainless steel coil used for

Stainless Steel Coils are one of the most demanded raw materials to construct buildings and manufacturing industries. In years Stainless steel coils have been widely employed in the manufacturing of anything from household appliances to industrial equipment due to their partic...Read more -

The uses and applications of alloy steel T11 tube

Alloy steel T11 tube are available in highest quality and grade also in various dimensions. Alloy steel T11 tube are available with international quality parameters. For the production of these tube, companies follow the strict guidance mentioned in manual. Alloy steel T11 tub...Read more -

The Spiral Welded Pipe Manufacturing Process

Steel strip coil, welding wire, and flux are the raw ingredients. Before being used, it must pass stringent physical and chemical tests. After the steel pipe is rolled, use automatic submerged arc welding to repair welding using single wire or double wire submerged arc weldin...Read more -

Common Surface Defects of Welded Steel Pipe

(1) Layered steel Layered wall steel pipe means that the cross section is divided into two layers, and the exposed steel plate surface presents vertical cracks in layers. Some of the internal and external surfaces of the display steel are locally depressed or bulged, and the d...Read more -

What is the difference between aisi and astm standards

Today, the formation of various systems make use of components that are manufactured all over the world. Global import export for metal components has been on a steady rise. And with each passing day, manufacturers across the world offer competitive prices, lead times, and min...Read more -

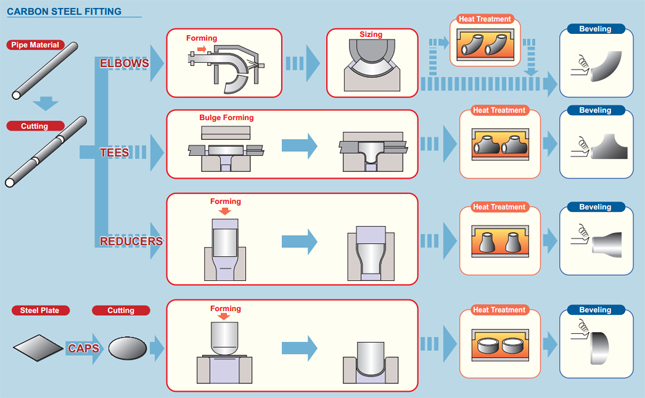

Butt-Welding Fitting Manufacturing Processes

Elbow Manufacturing Process a. Mandrel Method/Hot Forming Method One of the most common manufacturing methods for manufacturing Elbows from pipes. After heating the raw material, it is pushed over a die called “mandrel” which allows the pipe to expand and bend simultaneously. ...Read more