News

-

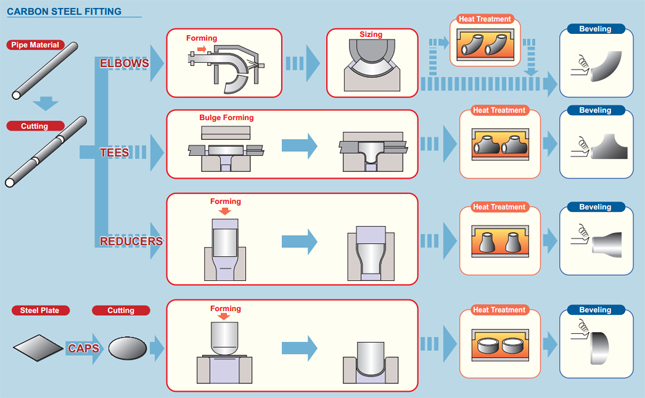

Butt-Welding Fitting Manufacturing Processes

Elbow Manufacturing Process a. Mandrel Method/Hot Forming Method One of the most common manufacturing methods for manufacturing Elbows from pipes. After heating the raw material, it is pushed over a die called “mandrel” which allows the pipe to expand and bend simultaneously. ...Read more -

ERW vs Spiral Pipes: What Are the Differences?

Both ERW Carbon Steel pipes and Spiral Pipes are used to transport oil, gas, and chemicals. They have similar utilities and applications. However, when you look further into their workings, one can find differences in various aspects. If looked into closely, one can point out ...Read more -

The difference between carbon steel VS cast steel

1. Different in nature Cast steel: Cast steel is a kind of casting alloy. Iron and carbon are the main elements. The carbon content is between 0-2%. Carbon steel: Carbon steel is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. Generally, it also contains a smal...Read more -

Types of Hollow Structural Sections

Hollow structural sections typically come in three main forms: rectangular hollow sections (RHS), square hollow sections (SHS) and circular hollow sections (CHS). Each type of hollow section has its benefits, properties, and purposes. Circular Hollow Sections The circular holl...Read more -

Hot-finished vs. cold-formed tubes

Electric Resistance welded (ERW) carbon steel tubes have been successfully used in building and industrial pipework installations for many years. However, we are now seeing the increasing use of imported, commodity welded tubes that may prove to be less suitable for typical pi...Read more -

The Four Types of Carbon Steel

Carbon steel can be categorized depending on the chemical composition and characteristics of the product. Mild steel also falls under the low carbon steel category as it is comprised of similar carbon content. Plain carbon steel is free from alloys and can be placed in four ca...Read more -

Tips for using ASTM A105 Carbon Steel Flanges for the first time

Use Slip-on Flanges in low-pressure services: Users more prefer slip-on flanges due to its affordability, quick & easy installations. ASTM A105 Carbon Steel Flanges used for non-critical low-pressure services like cooling water, firewater, and other non-challenging pipewor...Read more -

Applications and Benefits of SS 316L Pipes

Stainless Steel 316L Pipe is made up of austenitic stainless steel that has chromium, nickel, and molybdenum in its composition and it contains low carbon than the 316 grade. The low carbon content of the tubes facilitates welding applications. SS 316L pipe is used in aqueous ...Read more -

Difference Between SS 304 vs SS 316

While using steel, many people are confused between SS 304 and SS 316, which steel grade to use in the working environment so that the material used in the application should last for a long time. The material can be anything used in the form of fastener, bolt, rod, sheets, pl...Read more