News

-

Key points of internal thread tapping of stainless steel pipe fittings

1 Tap design and manufacture in the steel pipe fitting a. Choose a better tap material. Adding special alloy elements to ordinary high-speed tool steel can significantly improve the wear resistance and toughness of the tap. b. Coating titanium nitride coating into the surface ...Read more -

How to transport 3PE anti-corrosion steel pipes to ensure that the anti-corrosion layer is not damaged

3PE anti-corrosion steel pipe is a high-level anti-corrosion steel pipe. It is composed of three layers of anti-corrosion: primer + glue + PE. It has high corrosion resistance and wear resistance. The normal service life is about 30 years, mainly due to the quality of its anti...Read more -

The role of heat treatment of stainless steel pipe fittings

After stainless steel pipe fittings are processed by processes such as forming and welding, the metal molecular structure, magnetic properties, and physical properties change. The atmosphere-protected solid solution process can restore the corrosion resistance affected after p...Read more -

What are the requirements for stainless steel fluid tubes

Stainless steel fluid pipes are used to transport fluid substances and are used in food, pressure vessels, industrial transportation, and other industries. The pipelines used to transport fluids have very high process requirements. The most critical points are these: 1. Requir...Read more -

Anti-corrosion painting and development analysis of straight seam steel pipes

The performance and functions of the original color straight seam steel pipe in the specific use process fully demonstrate the operational contribution and usability. After painting and spraying white letters, the straight seam steel pipe also looks very energetic and beautifu...Read more -

Galvanized steel pipes installation steps

1. Pipe breaking: Draw a line on the selected galvanized steel pipe according to the on-site surveying and mapping sketch, and break the pipe according to the line. a. Use a grinding wheel to saw off the pipe. Place the pipe on the grinding wheel saw caliper, align it with the...Read more -

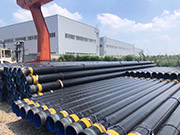

Product advantages of anti-corrosion steel pipes

1. Combine the mechanical strength of steel pipes and the corrosion resistance of plastics; 2. The outer wall coating is more than 2.5mm, resistant to scratches and bumps; 3. The friction coefficient of the inner wall is small, 0.0081-0.091, which reduces energy consumption; 4...Read more -

Steel structure connection method

Weld connection Connection method: Arc welding is mainly used to connect welds in steel structures. That is, at the connection point of the components, the high temperature generated by the arc melts the welding rod or wire metal placed in the welding part to connect the compo...Read more -

Diameter expansion technology and classification of straight seam steel pipes

In terms of the welding process, the welding methods of spiral welded pipes and straight seam steel pipes are the same, but straight seam welded pipes will inevitably have many T-shaped welds, so the probability of welding defects is also greatly increased, and the welding res...Read more