News

-

Difference between ASTM A249, A269, A270, and A554 Stainless steel tubing

Surface Finish A249 and A269 both require Surfaces “free of scale” – annealing of the tube is normally done in a controlled atmosphere and this “bright annealed” finish is considered acceptable. A270 requires selection of both internal and external Surfaces. The possible condi...Read more -

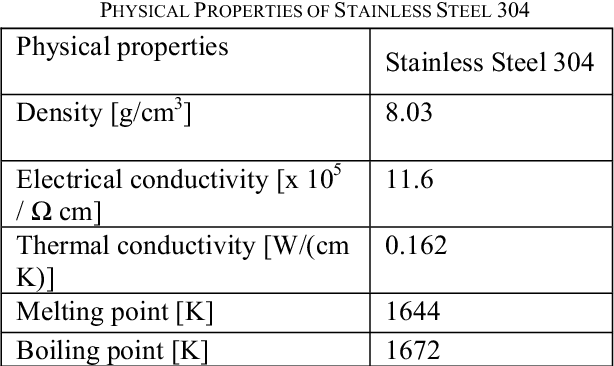

Physical Properties of 304 Steel

Stainless steels get their names from the American Iron & Steel Institute (AISI) and the Society of Automotive Engineers (SAE), who have separately created their own naming systems for steel alloys based on alloying elements, uses, and other factors. Steel names can get c...Read more -

How is the weld stainless steel pipe produced

1. Splitting : Splitting rolls with bigger sizes into rolls with smaller sizes according to each size tubes or to customer’s requirements rolled through the tape discharge system. This stage requires precision in terms of the size belonging to the tape according to the given t...Read more -

General Knowledge of Alloy Steel Pipes

General knowledge of alloy steel pipes: the brief introduction, chemical compositions, heat treatment perfomance and smelting equipment. 1. The brief introduction of alloy steel pipes Alloy steel pipes have hollow sections. A large number of alloy steel pipes are used for conv...Read more -

Specifications of Stainless Steel

Grade compositions, mechanical properties and production specifications are governed by a range of international and national standards for stainless steel. While the old AISI three digit stainless steel numbering system (e.g. 304 and 316) is still commonly used for the classi...Read more -

Types of Industry where Stainless Steel Pipe is Used

Let’s look at the industries stainless steel pipes are used in. Oil and Gas Technology plays a massively important role in the oil and gas industries. The need for corrosion-resistant piping has increased over the past couple of years as the depths we explore for oil deepens a...Read more -

Uses and Advantages of Seamless Pipe

Seamless pipes one of the best industrial needs today. Most of the industries right automobiles, a nuclear device, shipbuilding, boiler, gas and petrochemical industries are largely dominated by Seamless Pipes. Advantages of seamless steel pipe Increased Pressure Ratings The g...Read more -

How to Choose Between 316 or 316L Stainless Steel

When determining whether to use 316 or 316L stainless steel for your application, it is important to consider the following factors: Corrosion Resistance 316L is the superior choice for high corrosion and high temperature applications. Since 316L contains less carbon than 316...Read more -

LSAW, SSAW, and ERW Pipes Description and Comparison

There are 3 main methods of production for welded tube and pipe electric-resistance (ERW), longitudinal (LSAW or DSAW), and spiral welded(SSAW). Longitudinally Submerged Arc Welding Pipes LSAW Pipe (Longitudinal Submerged Arc-Welding Pipe), also called SAWL pipe. It is taking...Read more