Product Information

-

Surface treatment of thick-wall straight seam steel pipe

The uniformity of the pipe wall of the thick-walled straight seam steel pipe will directly affect the post-processing parts. The pipe wall of the thick-walled straight seam steel pipe cannot be controlled, and the overall steel pipe cannot be strictly controlled. Small and med...Read more -

What are the classifications of the coating methods of large-diameter water-conveying plastic-coated steel pipes

The coating methods of large-diameter water-conveying plastic-coated steel pipe plastic-coating equipment are divided into two categories: simultaneous internal coating and external coating, and separate internal coating and external coating. Process coating methods are also d...Read more -

Technical characteristics of spiral steel pipe

Spiral steel pipes are mainly used in tap water engineering, the petrochemical industry, the chemical industry, the electric power industry, agricultural irrigation, and urban construction, and are twenty key products developed. For liquid transportation: water supply, drainag...Read more -

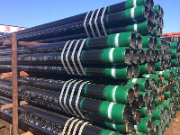

Anti-corrosion Countermeasures for Oil Casing

1. First of all, do a good job of water quality standards, and strictly monitor and manage water quality. Implement cleaning and separate injection, strengthen the cleaning of the main water pipeline, ensure that the water quality in the station and the bottom of the well meet...Read more -

Welding treatment of thick-walled spiral steel pipe

Thick-walled spiral steel pipe is a method of arc welding under the flux layer, which is formed by using the heat generated by the arc burning between the flux and the welding wire under the flux layer, the base metal, and the melting wire flux. In the process of use, the prin...Read more -

Hardness index of anti-corrosion spiral steel pipe

The ability of metal materials to resist the indentation of the surface of hard objects is called hardness according to different test methods and application ranges. The hardness can be divided into Vickers hardness, Shore hardness, Brinell hardness, Rockwell hardness, microh...Read more -

What are the factors that affect the performance of the steel pipeline

Factors that degrade pipe materials or affect their function include pH, soil and water resistivity, abrasion resistance, chloride, sulfate or acid corrosion, fire resistance, crack propagation and oxidation of thermoplastics and electrochemistry of steel corrosion. The above ...Read more -

Safety protection in the construction of anti-corrosion steel pipe

At present, the more commonly used steel pipes are anti-corrosion steel pipes. There are mainly 3PE anti-corrosion steel pipes, TEPE anti-corrosion steel pipes, epoxy resin anti-corrosion steel pipes, etc. So, what should be paid attention to during the construction of anti-co...Read more -

Connection method of the natural gas three-way valve

1. The two outlet pipes with valves are connected to gas-consuming devices (such as gas stoves, barbecue stoves, water heaters, heaters, etc.). The rest is the inlet of the intake pipe, which should be connected to the inlet pipe of the pipeline gas meter or the pressure-reduc...Read more